Precision aluminum casting checklist for efficient production

Wiki Article

Learn Exactly How Foundry Services Can Transform Your Manufacturing Capabilities

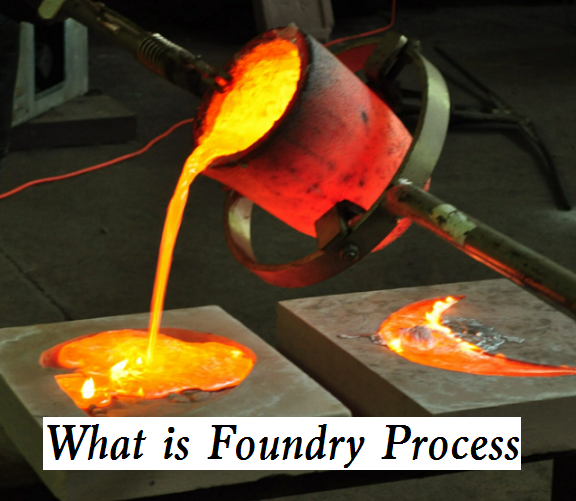

Foundry services have become a crucial part in modern production. They offer advanced innovations that improve manufacturing performance and accuracy. By incorporating devices like 3D printing and automation, these services make it possible for companies to respond promptly to market demands. However, the potential of shop services prolongs beyond simple effectiveness. What certain advantages can they bring to your functional method? Discovering this could reveal substantial chances for growth and development.The Duty of Foundry Services in Modern Production

As industries progressively require specialized parts, the function of foundry services in modern-day manufacturing has actually become vital. Factories function as substantial companions, giving the needed know-how and modern technology to produce top notch steel parts customized to certain applications. These services facilitate the creation of intricate layouts, allowing suppliers to innovate while maintaining effectiveness.By leveraging foundry abilities, business can access a variety of materials, including numerous alloys and steels, ensuring that they satisfy both efficiency and regulative standards. Furthermore, shop services make it possible for fast prototyping, enabling companies to test and improve their styles prior to full-blown production. This flexibility not just improves item top quality but likewise lowers time-to-market, giving business an affordable edge.

Eventually, the combination of foundry services right into the manufacturing process supports a much more responsive and vibrant production environment, vital for fulfilling the developing needs of different industries.

Secret Technologies Driving Foundry Innovations

Developments in shop services are significantly influenced by developments in technology, which boost production capacities and efficiency. Trick technologies such as 3D printing, computer-aided layout (CAD), and automation are transforming standard foundry processes. 3D printing permits for rapid prototyping and complicated geometries, minimizing material waste and lowering lead times. CAD software application helps with specific design and simulation, allowing designers to identify prospective concerns before production begins. Automation, consisting of robotics and synthetic intelligence, enhances procedures, boosting consistency and decreasing human mistake.Furthermore, the combination of the Net of Points (IoT) into foundry procedures makes it possible for real-time surveillance and data collection, optimizing resource management and upkeep timetables. These technologies collectively add to a more active and receptive manufacturing setting, allowing shops to adapt rapidly to market needs. As these developments proceed to develop, they assure to redefine the landscape of factory services and boost total production effectiveness.

Advantages of Outsourcing Foundry Services

Contracting out shop services provides numerous calculated advantages that can significantly boost functional effectiveness and cost-effectiveness for manufacturers. By partnering with specialized foundries, business can access advanced innovations and proficiency that might not be available in-house. This partnership enables producers to concentrate on their core expertises while leveraging the shop's abilities for production processes.Furthermore, outsourcing can lead to significant cost financial savings. Suppliers can decrease overhead expenses connected to labor, devices maintenance, and facility administration. This versatility enables scalability; business can change production quantities based on market need without the burden of repaired costs.

Additionally, contracting out shop services usually causes boosted preparations and product high quality. Knowledgeable shops have established methods and high quality control actions that ensure consistency and dependability. In general, outsourcing foundry services gives suppliers with the required tools to remain affordable check out this site in a rapidly evolving marketplace.

Case Studies: Success Stories in Foundry Applications

When suppliers leverage foundry services effectively, they commonly attain impressive results that underscore the potential of such partnerships. A notable case study entailed a vehicle business that partnered with a shop to produce light-weight light weight aluminum elements. This cooperation not just reduced manufacturing time by 30% yet additionally boosted fuel effectiveness in their automobiles, showcasing the influence of innovative materials.A medical tool manufacturer used shop services to develop accuracy parts for surgical tools. By using innovative spreading strategies, the supplier boosted item reliability and decreased problems, resulting in a 25% boost in market share.

In another circumstances, an aerospace firm worked with a shop to create intricate wind turbine parts. The use of sophisticated production processes caused a significant decrease in weight, enabling better aircraft efficiency. These success tales illustrate exactly how effective collaborations with factories can drive development, efficiency, and affordable benefit throughout different markets.

Future Fads in Foundry Services and Production Efficiency

As markets proceed to advance, the future of factory services is poised for significant innovations that promise to boost production efficiency. Trick patterns include the combination of automation and robotics, which enhance processes and reduce labor prices. In addition, the adoption of artificial knowledge (AI) and artificial intelligence makes it possible for predictive upkeep, minimizing downtime and optimizing resource allotment.

Sustainability will additionally play a vital duty, with factories increasingly more helpful hints focusing on energy-efficient techniques and the use of recycled products. This change not only straightens with environmental objectives yet also minimizes operational costs. The execution of real-time information analytics will enhance decision-making, permitting for quicker adjustments in manufacturing lines.

Lastly, innovative products and 3D printing technologies are readied to reinvent the typical factory landscape, enabling the manufacturing of intricate geometries and personalized components. Jointly, these patterns represent a transformative era in factory services, driving performance and advancement in production capacities.

Frequently Asked Questions

What Sorts of Products Are Typically Made Use Of in Foundry Services?

Common materials utilized in factory services consist of steels such as iron, aluminum, and steel, together with alloys. Aluminum Foundry. Additionally, sand, ceramic, and other mold materials play vital functions in shaping and forming the last itemsJust How Do Foundry Services Make Certain Top Quality Control in Manufacturing?

Foundry services assure quality assurance with rigorous evaluations, standardized processes, and adherence to industry policies. Advanced innovations, like real-time tracking and testing, even more enhance uniformity and dependability in manufacturing, causing remarkable end products.What Are the Ecological Influences of Foundry Services?

Foundry services can add to ecological effects with emissions, waste generation, and source intake. Appropriate administration practices, consisting of recycling and exhausts manage, are essential to minimize these adverse impacts and promote lasting production processes.Just How Can Foundry Services Assistance Small Companies?

Foundry services can support local business by supplying access to specialized production abilities, reducing manufacturing prices, offering versatile production ranges, and allowing much faster item advancement, ultimately cultivating development and competition in diverse markets.What Qualifications Should Foundry Company Have?

Foundry provider need to possess certifications such as ISO 9001 for high quality management, AS9100 for aerospace criteria, and NADCAP for special procedures - Aluminum Casting Company. These certifications ensure compliance with market criteria and enhance trust fund in their capabilitiesThe possibility of shop services extends past simple efficiency. In enhancement, shop services allow quick prototyping, allowing organizations to test and fine-tune their designs before major production. Advancements in shop services are considerably affected by developments in innovation, which boost production capabilities and effectiveness. Outsourcing shop services offers a number of calculated benefits that can greatly enhance functional effectiveness and cost-effectiveness for manufacturers. As sectors continue to advance, the future of factory services is check my reference positioned for substantial advancements that promise to enhance production effectiveness.

Report this wiki page